Understanding the Demands on Hall Sensors for Automotive Applications

By Charles Kuo, Sensor Product Line Manager

The demand for compact, accurate position sensors in automotive applications will grow substantially to $1.6 billion by 2026, in line with the growth in electric vehicles (Figure 1). These sensors track the rotor’s position inside the motor responsible for traction, power steering, and windows; ensuring control and safety coverage. First, this article reviews legacy approaches to proximity, position detection, and their limitations. It then considers the operation and advantages of magnetic proximity and position sensors, based on the Hall effect, before discussing the factors which limit their use in automotive applications. Finally, it presents a series of Hall-sensor switches/latches that enable automotive systems to achieve the highest levels of automotive safety certification: ISO 26262.

Figure 1. Vehicle electrification is driving the demand for position and proximity sensors

Problems with legacy position-sensing technologies

Potentiometers, optical encoders, and resolvers were most widely used for position-sensing, but each has shortcomings that impact their use in automotive applications.

Potentiometers use physical contact to measure rotary motion. However, this means they are subject to mechanical wear and tear caused by friction, and performance can be affected by shock or vibration. In addition, contamination of the resistive element by foreign substances like dirt, dust, moisture, or grease can impair performance and even lead to premature failure.

Optical encoders measure position by detecting alternating light and dark areas as a disk with cut-out holes (often called a code wheel) rotates between an LED light source and a photodiode sensor. They are vulnerable to contamination however, which lowers reliability by interfering with the light source and detector. Another disadvantage of optical encoders is that they are bulky (a problem in space-constrained automobiles) and must be assembled precisely to have very low tolerances.

Resolvers use an electromagnetic transducer to measure position at high rotational speeds. While they are accurate, they are large and heavy, which increases costs and furthers incompatibility with small-space automotive applications.

Magnetic sensors—smaller, lighter, and lower cost

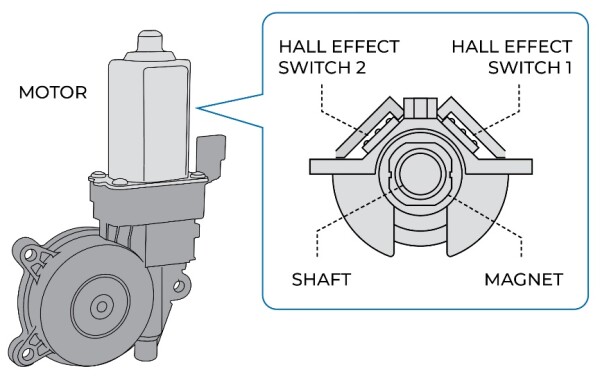

Hall-effect (or Hall) sensors (Figure 2) typically include one or more embedded magnetic elements. When an external magnetic field comes into the proximity of the sensor, it alters the polarity and strength of the embedded magnetic field. As this varies, the potential difference across the sensor changes, and this can be used to track changes in an external magnetic field. For example, simple magnetic switches detect the opening and closing of a window or door (Figure 2) using a Hall sensor and a magnet on either side of the locking mechanism.

Figure 2 – Hall sensors controlling a motor to open/close a car window

Hall-sensor technology evolved to enable precise and accurate linear- and rotary-positioning measurements in many applications. A rotary position sensor can be implemented using a simple assembly, consisting of a fixed sensor board mounted perpendicular to a rotating magnet mounted on-axis on the shaft of the rotor.

Manufacturers developed the capability to produce Hall sensors in an integrated circuit (IC) on a standard, complementary metal-oxide semiconductor (CMOS) fabrication process, making their high-volume production more cost-effective. Therefore, magnetic position sensors are smaller, lighter, and less expensive than other sensor technologies.

Automotive requirements for the use of Hall sensors

Instead of using mechanical or hydraulic actuation, electronic control in functions like steering and gear change improves performance, increases reliability, and reduces size and weight. Some of the automotive applications where these features are essential include:

- Power steering motors

- Chassis positioning

- Dual-clutch transmissions

- Traction motor positioning in hybrid-electric and fully electric vehicles

- Steering angle detection

The lower weight of Hall sensors assists car manufacturers in reducing fuel consumption, while the smaller size improves mechanical design flexibility. While the appeal of using Hall-sensor technology for automotive applications is obvious, the automotive industry has specific requirements about quality, reliability, and safety for safety-critical functions, prohibiting commodity and general-purpose Hall sensors.

These cover:

Quality

Safety certifications and the Automotive Engineering Council’s standards specify the exact requirements for repeatability, traceability, and production quality. These apply not just to individual components, but also to the complete sensor system assembly.

Under each of these headings, general-purpose Hall sensors do not conform to the automotive sector’s typical performance specifications, meaning these general sensors potentially expose automotive OEMs to an elevated risk of failure. Some general-purpose magnetic position sensors previously installed in production vehicles presented reliability issues and safety concerns for vehicle manufacturers.

The leading cause of problems is external magnetic interference. Automobiles are electrically noisy environments with many stray magnetic fields that can distort the signal sensed by the IC, interfering with the operation of a magnetic sensor. This can cause measurement errors that impact the accuracy of the sensor’s position readings. In an EV traction motor, for example, these errors could lead to a severe reduction in or even a complete loss of torque or unpredictable wheel rotation.

Reliability

Devices used in critical automotive applications are expected to operate in a wider temperature range than that expected for consumer or industrial devices. They are also specified to operate over a minimum lifetime of ten years. Issues have arisen about the repeatability of assembly production. Hall sensors measure position relative to a paired magnet mounted on the motor shaft, which rotates relative to a static sensor with a small air gap between them. Some manufacturers have faced quality problems achieving assembly tolerances during production.

Safety

The use of magnetic position sensors has also been reviewed following the adoption of the ISO 26262 functional safety standard. This standard requires a rigorous Failure Modes Effects and Diagnostic Analysis (FMEDA) to be performed at the system level, and to implement adequate safety countermeasures in combating the risks associated with known failure mechanisms. Commodity magnetic position sensors do not have the features required to guarantee system safety during a device failure, and are also not supported by ISO 26262-compliant development, production processes, and documentation.

Automotive-qualified Hall-sensor switches/latches

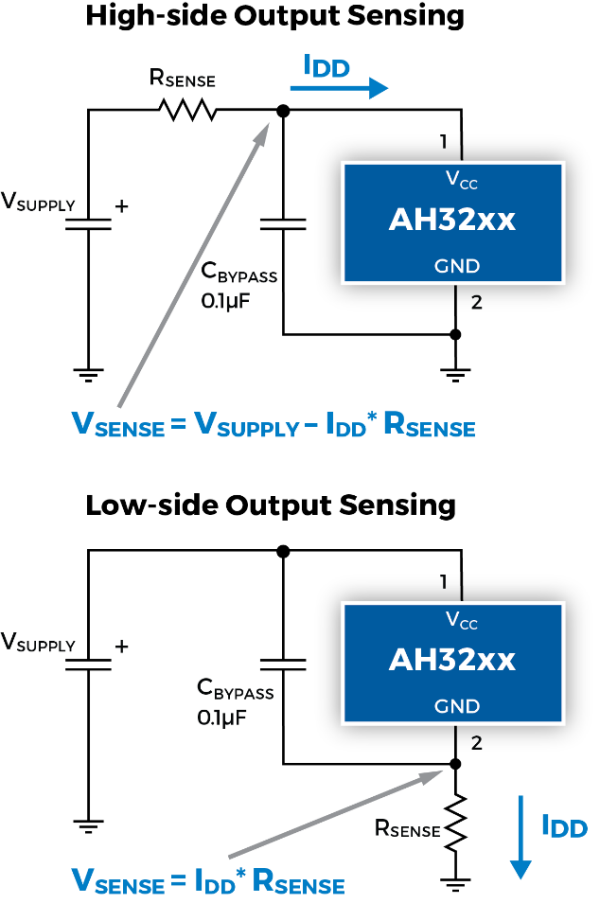

The AH32xxQ series of two-wire, Hall-sensor, unipolar switches and latches by Diodes Incorporated is based on an advanced design that enables automotive systems manufacturers to achieve ISO 26262-compliant position- and proximity-sensing systems. These ICs are AEC-Q100 qualified, manufactured to the highest standards in IATF 16949-certified sites, and have supporting PPAP documentation. They also provide high sensitivity (AH3270Q/71Q & AH3280Q/81Q) and robustness (8kV ESD withstand capability). These sensor ICs require only two wires, reducing overall system cost in especially long-wire harnesses. Unlike most Hall-sensor switches (which have a voltage output), these devices provide a current output that is more resilient than the voltage in the presence of noise spikes (Figure 3). For flexibility, they have been designed to operate over a wide voltage range (2.7V to 27V) and are supplied in industry-standard SC59 and SIP-3 packages.

Figure 3 - A current output is more resilient than voltage in the presence of noise spikes

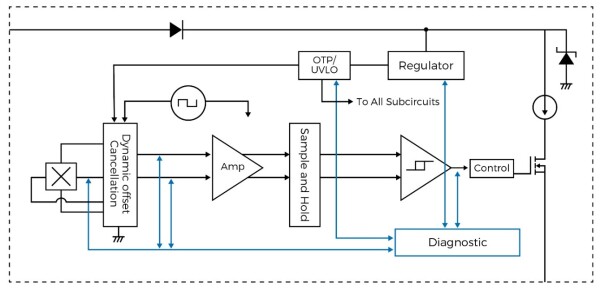

Integrated self-diagnostic functions (AH324xQ and AH328xQ) make them ideal for ASIL-compliant systems, which require high levels of functional safety (Figure 4). These features operate in the background without external activation. If an error is detected, the device enters a “safe mode” of operation where the output (supply) current drops to 1mA, serving as a warning flag to the rest of the system. In addition, the integrated self-diagnostics monitor supply voltage and temperature, and self-tests major functional blocks.

Figure 4 - Functional diagram showing self-diagnostic features of the AH324xQ/AH328xQ

Conclusion

Vehicle electrification is a significant driver behind the growing number of motors in automobiles, which in turn is creating the requirement for a small, lightweight, reliable, and low-cost sensor to track their speed and position. Magnetic position and proximity sensors based on the Hall effect offer such a solution; however, commodity versions are unsuitable for automotive applications because they do not allow position-sensing systems to meet critical safety standards like ISO 26262.

The AH32xx range of Hall switches/latches by Diodes Incorporated has been specially designed to have a wide operating voltage range to increase their sensitivity and current output signaling to improve robustness in the presence of voltage spikes. Some devices in this family also include self-diagnostic features which enable sensor subsystems to achieve the safety certifications required for automotive applications.

The Diodes logo is a registered trademark of Diodes Incorporated in the United States and other countries.

All other trademarks are the property of their respective owners.

© 2023 Diodes Incorporated. All Rights Reserved

This article originally appeared in CIE's Digital Newsletter on April, 2023.